Products

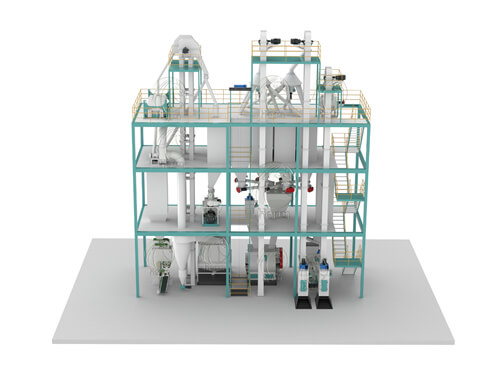

Leading Manufacturer & Exporter of the different capacities of animal feed production lines . It is also known as feed production line, feed pellet production line, feed pellet line, feed pellet plant, cattle feed plant, poultry feed plant, chicken feed mill, livestock feed processing machine, etc. It is mostly used for making poultry feed, cattle feed, livestock feed, pig feed, sheep feed, chicken feed, goat feed, etc. Different capacities and sizes for you to choose from, it also can be custom according to your need.

We entertain enquiries from international markets.

-

Feed Production Line

35-40T/H Feed Pellet Line

30-35T/H Feed Pellet Line

20-30T/H Feed Pellet Line

View All -

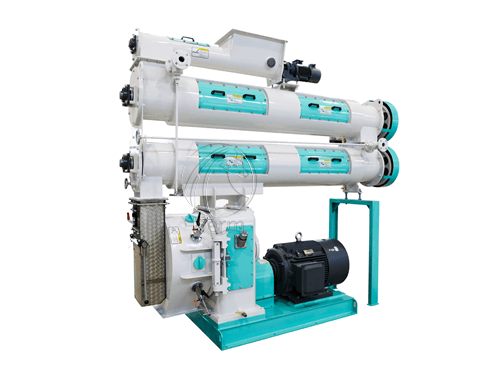

Feed Pellet Machine

HM Belt Type Feed Pellet Mill

SZLHM Grass Feed Pellet Machine

HMLH678 Feed Pellet Mill

View All -

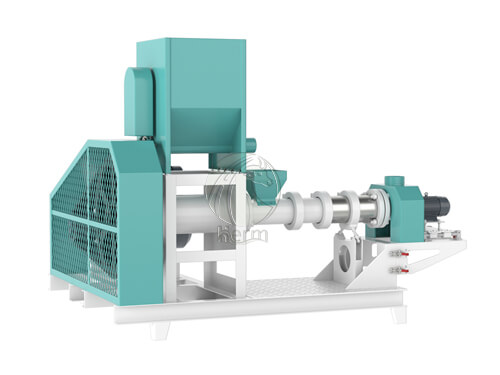

Feed Extruder

DSP Fish Feed Extruder Machine

DGP Fish Feed Extruder Machine

Twin-screw Feed Extruder

View All -

Cleaning Machine

TCXT Permanent Magnet Sleeve

TYDM Pulse Dust Collector

SCQZ Powder Feed Screener

View All -

Chipper & Crusher

SFSP Wood Hammer Mill

Water Drop Hammer Mill

SSLG Feed Crumbler

View All -

Feed Mixer

SLHY Ribbon Mixer

SLHS Shaft Paddle Mixer

Single Shaft Paddle Feed Mixer

View All -

Feed Dryer & Cooler

Roller Drying Machine

SKLN Counterflow Cooler

Convection Belt Dryer

View All -

Feed Packing Machine

Automatic Packing Machine

View All -

Wood Biomass Pellet Plant

3-3.5T/H Wood Pellet Production Line

2-2.5T/H Wood Pellet Production Line

1-1.5T/H Wood Pellet Production Line

View All -

Wood Pellet Machine

MZLH768 Wood Pellet Mill

MZLH520 Wood Pellet Mill

MZLH420 Wood Pellet Mill

View All -

Storage Silos

Galvanized Silo

Hopper Silo

Flat Bottom Silo

View All -

Other Related

WNS Steam Boiler

LSS Steam Boiler

Horizontal Screw Conveyor

View All