What Are the Precautions in Using Animal Feed Production Line Processing

There are many kinds of feed processing equipment, among which the key equipment affecting feed granulation is nothing more than a hammer mill crusher, mixer, and poultry feed-making machine. Feed manufacturers need to understand the precautions for using the equipment.

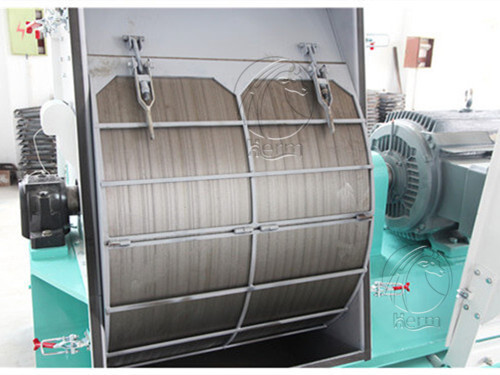

1. Hammer Mill Crusher

The hammer mill crushers generally have vertical and horizontal types. The main components of the crusher are the hammer and screen. The hammer shall be durable, wear-resistant, and have certain toughness.

Precautions for the use of a crusher:

1) Before starting the machine, check the lubrication of all parts of the connectors and bearings. Run the machine empty for 2-3 minutes, start feeding after a normal operation, stop feeding after work, and run the machine empty for 2-3 minutes. Turn off the motor after all the materials in the machine are drained.

2) If the hammer blade is worn to the centerline, it should be turned around immediately. If all four corners are worn to the center, a new hammer piece needs to be replaced.

Note: the original arrangement order shall not be changed during replacement, and the weight difference between each group of hammer pieces shall not exceed 5g, otherwise the balance of the rotor will be affected.

3) The air net system of the crusher is very important to improve the crushing efficiency and reduce dust. It should be matched with a pulse dust collector with good performance.

4) The materials shall not be mixed with an iron block, gravel, or other sundries. If an abnormal sound is heard during work, stop the machine in time for inspection and troubleshooting.

2. Feed Mixer (double shaft mixer as a sample)

The double-shaft feed mixer is composed of a casing, rotor, cover, discharge structure, transmission device, etc. The blade shaft intersects the main shaft, and the blade is welded on the blade shaft at a special angle. On the one hand, the blade with animal materials rotates along the inner wall of the machine slot and moves to the other end, the animal materials turn over and cross-cut each other, to achieve the effect of rapid and uniform mixing.

Precautions for the using mixer:

1) Feed the materials after the main shaft rotates normally. The additives shall be added after half of the main materials enter the batch. The grease shall be sprayed after all dry materials enter the machine. The materials can be discharged after spraying and mixing for a while time;

2) When the machine is not in use, the grease shall not be retained in the grease-adding pipeline to avoid blocking the pipeline after solidification;

3) Metal impurities shall not be mixed during material mixing, which will damage the rotor blade;

4) In case of a shutdown during use, discharge the materials in the machine before starting the motor;

5) If the discharge door leaks material, check the contact between the discharge door and the sealing seat of the casing. If the discharge door is not closed tightly; Adjust the position of the travel switch or the adjusting nut at the bottom of the material door, or replace the sealing strip.

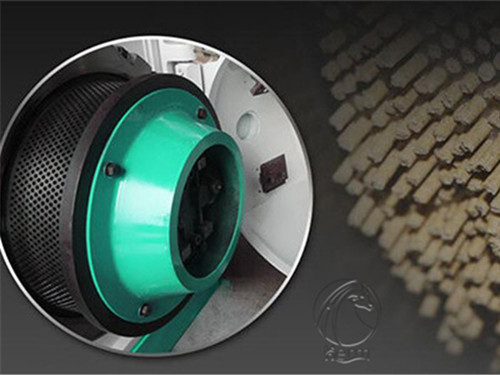

3. Ring Mold Feed Pelletizer

Feed pellet mill machines are the main equipment in the production process of poultry feed equipment, which can also be said to be the heart of feed plants. The correct use of feed pellets directly affects the quality of finished products.

Precautions for the using feed pelletizer:

1) During production. When too many materials enter the feed fertilizer, and the current rises suddenly, need use manual unloading of the materials outside the feed granulator is done.

2) When it is necessary to open the door of the feed pelletizer, the power supply must be cut off first, and the door can be opened only after the feed pelletizer completely stops running.

3) When the machine breaks down, the electric power must be cut off, and the machine must be shut down for troubleshooting. It is strictly prohibited to use hands, feet, wooden rods, and irons for hard troubleshooting during operation; It is forbidden to start the motor hard.

4) When the new ring mold is used for the first time, a new pressing roller must be used. The ring mold can be washed for 10 to 20 minutes with oil mixed with fine sand (all pass through a 40-20 mesh sieve, and the ratio of material∶oil∶sand is about 6∶2∶1 or 6∶1∶1). Then ring die can be put into normal production.

5) Check and refuel the main motor bearing once a year.

6) Replace the lubricating oil for the gearbox of the feed pelletizer once or twice a year.

7) The steam pressure entering the jacket of the conditioner shall not be higher than 1kg/cm2.

8) Clean the feeder and conditioner 2-4 times a week (once a day in summer).

9) The distance between the cutter and the ring die is generally not less than 3mm.

10) During production, overload operation is strictly prohibited when the current of the main motor exceeds the rated current.

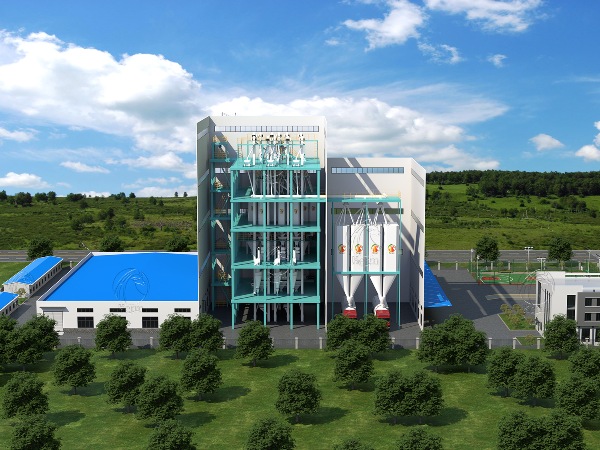

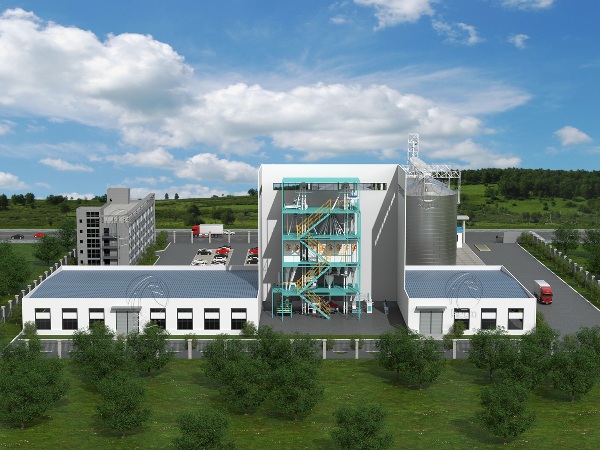

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Phone/Whatsapp: 86-18037508651