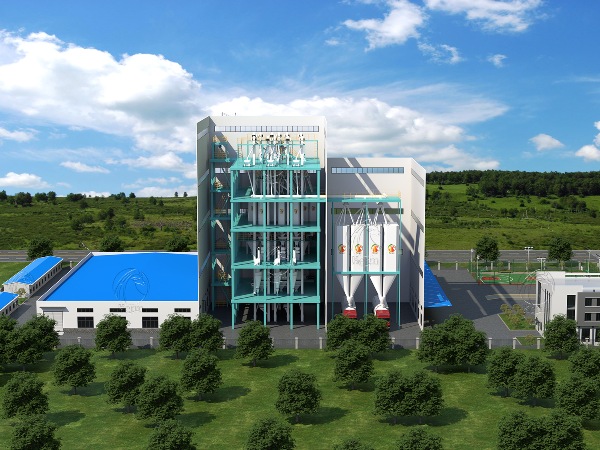

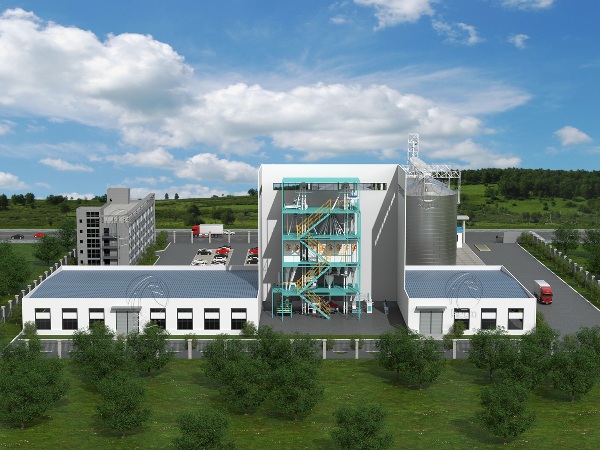

1-1.5t/h Biomass Wood Pellet Production Line Introduction

Herm Machinery Super High-Quality 1-1.5T/H Biomass Wood Pellet Production Line is specially designed for all manufacturers based on the principle of biomass recycling, such as biomass fuel manufacturers, wood board factories, organic fertilizer factories, feed factories, carton factories, etc. The main process flow of 1-1.5t/h biomass wood pellet production line: raw material crushing, drying, granulating, cooling, screening, and packaging. The main equipment of the complete 1-1.5 t/h biomass wood pellet machine equipment includes a wood chipper, wood hammer pulverizer, drum rotary dryer, wood pellet machine, countercurrent cooler, vibrating screen classifier, automatic bagging system, electric control cabinet, etc.

Make a Quick Inquiry Now !

Raw Materials Of Biomass Wood Pellet Production Line

1-1.5t/h biomass wood pellet production line is mainly suitable for the production of wood, sawdust, wood chips, shavings, logs, branches, straw, rice husk, organic fertilizer, chicken manure, cow manure, pig manure, horse manure, peanut shells, palm trees, oil palm leaves, palm fiber, alfalfa, bagasse, forestry waste, hops, straw, hemp, palm kernel shells, waste paper, hay, etc.

How To Make Biomass Wood Pellet?

Chipping: Use a chipper to chop straw, branch materials, and large pieces that cannot be directly crushed into small pieces.

Crushing: Agricultural and forestry wastes are pulverized by a pulverizer to make the particle size less than 5mm. The pulverizer is only equipped with an inlet and an outlet. Close the feed port after feeding to reduce dust escape. The outlet is connected to the cyclone separator. The cyclone separator uses the principle of centrifugal force to separate the lower chips, the lower chips are deposited in the dust collector, the gas is discharged through the discharge port, and the gas is discharged from the cyclone separator and then processed by the bag filter. All collected dust is recycled to the production line.

Drying: Some raw materials that account for 30% of the total have a moisture content of 55% (the data provided by the owner is between 50% and 60%, and this environmental assessment takes 55%), which does not meet the requirements of the granulation Claim. These raw materials with excessive moisture content need to be dried to make the moisture content meet the granulation requirements (the moisture content is less than 13%), and the moisture content of the raw materials after drying is about 10%. The dryer of this project is equipped with a biomass wood burner, and the fuel is biomass wood pellets produced by the project.

Conveying and feeding: The raw material is sucked into the feeding port of the granulator through the feeding screw.

Granulation: The raw materials are fed into the granulator through the feeding auger, and then extruded to make the finished product. The extrusion process is a physical process, without any adhesive, no chemical reaction occurs, except that the feed screw connection device is sealed at the discharge port and the outside. This process mainly produces noise and high-temperature dusty waste gas;

Elevation and conveying cooling: The granulated biomass wood pellets are conveyed and cooled naturally to make their temperature reach the packaging and storage conditions, and finally conveyed to the finished product warehouse. This process creates dust and noise.

Packing: The compressed hot particles pass through the screening at the end of the conveyor belt, and the qualified biomass particles fall into the finished product bin. The bottom of the finished product bin is a funnel-shaped outlet. The finished product can be thrown directly into the bag. After the machine is packed, it can be stacked for sale. The shaped biomass sawdust particles have been compacted and dense, and there is basically no dust during the bagging process. Unqualified products are discharged collected and returned to the granulation process.

Make a Quick Inquiry Now !

Biomass Pellet Application

Animal bedding: Biopellets made of coniferous wood a high-grade animal bedding for the experience of raising animals.

Industrial boilers: Bioparticles can partially (or fully) replace coal or fossil fuels for co-firing heating in large-scale industrial operations to reduce energy costs.

Power plants: Biomass pellets can be used in power plants to solve the problem of insufficient power supply.

Building heating: Biomass pellets can be used in pellet stoves or furnaces to heat rooms in schools, hospitals, markets, companies, etc. It is also possible to use biomass pellets for cooking.